Learn more about how to make sure your file is suitable for 3D printing in grey resin and how to optimize it.

File Format & Size

The format required for 3D printing in grey resin is .STL or .OBJ. All models have to be under 100mb.

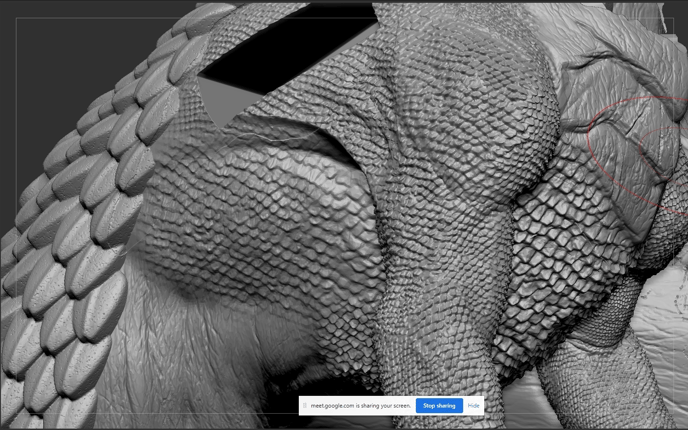

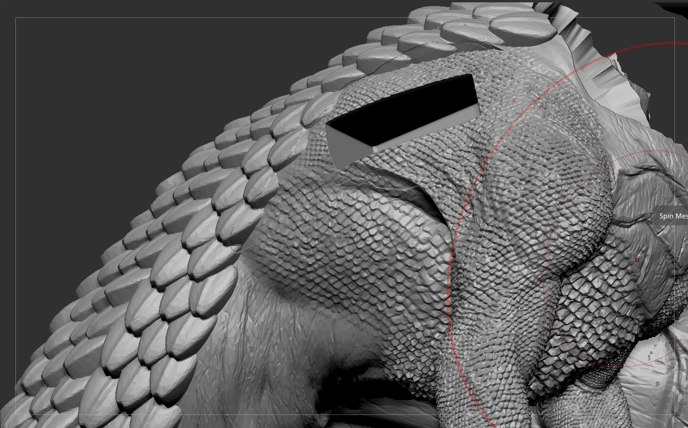

Decimation process helps to reduce the file weight without dramatically decreasing details quality. The images show the difference between original 500mb file and decimated 97mb result.

Hollowing

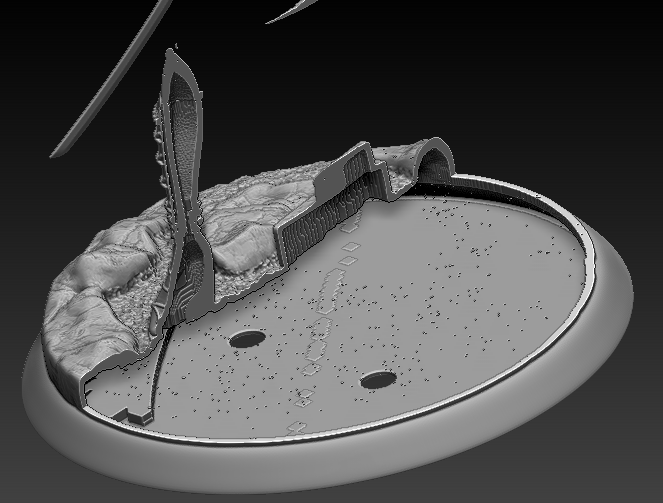

Hollowing of the model will reduce the manufacturing cost, because the volume would be lower. Minimum wall thickness required for printing in Grey Resin is 3mm.

SLA printing technology requires “escape hole(s)” in the model to drain out material. These should be ideally based where you can’t see them so underneath the base or behind the model is best There should be one or two holes minimum 3.5mm in diameter.

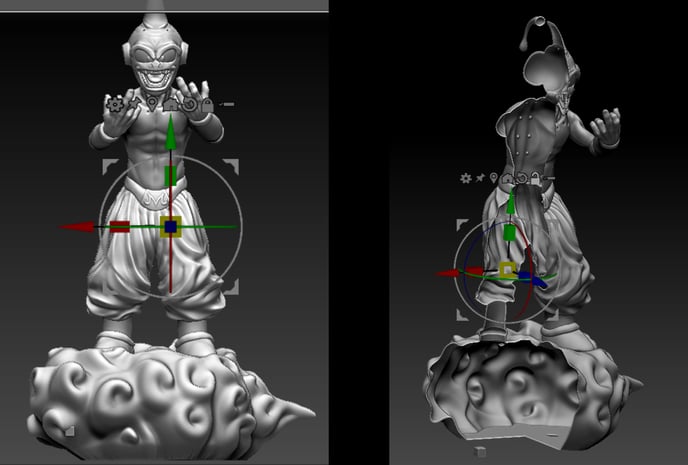

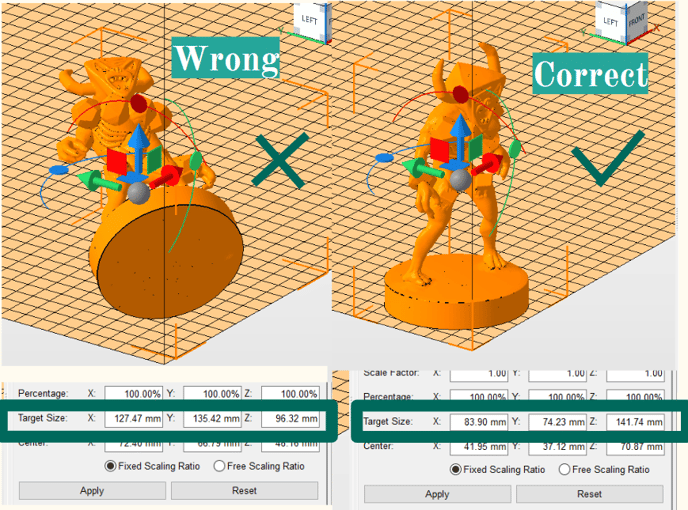

Dimensions & Orientation

For the model to be accessible for grey resin it has to have the correct orientation to fit the bed size, this can mean flipping/rotating the model, so that your longest dimension stills fits within the print bed parameters. Print bed size for grey resin is 266 x 145 x 390mm

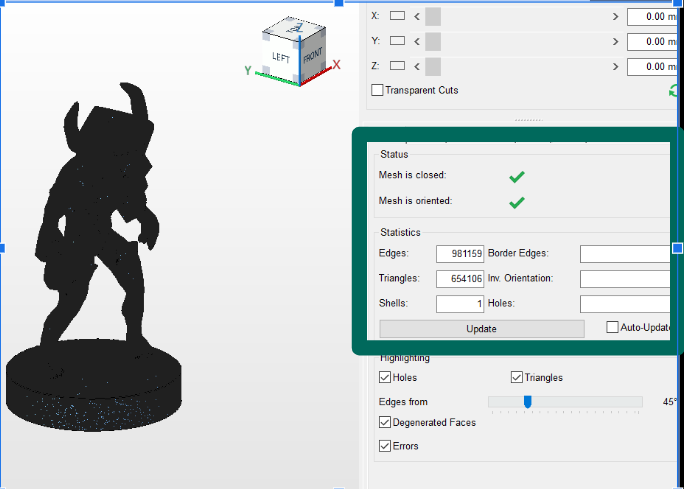

Mesh & Details

Mesh needs to closed, oriented and single. Minimum details thickness - 2mm. We recommend Autodesk Netfabb for checking and healing 3D models. Free trial available - https://www.autodesk.com/products/netfabb/overview

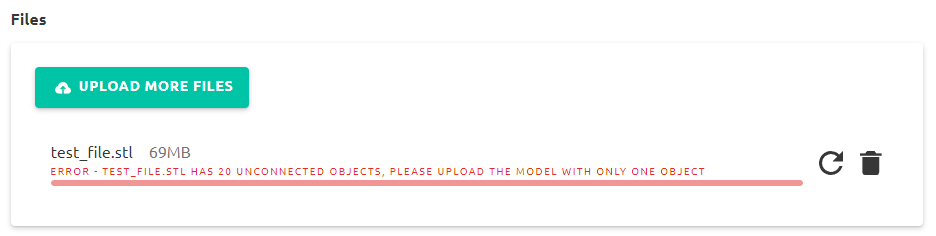

Unconnected Objects

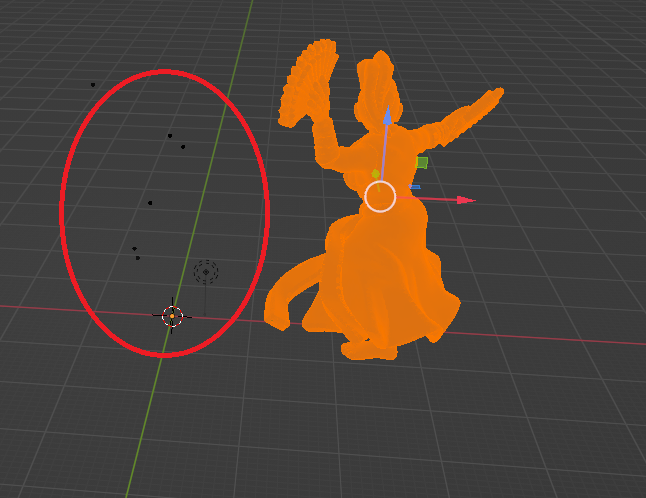

Uploaded models need to be a single, conjoined mesh and cannot contain unconnected parts within the same file.

If attempted, you will be met with the following error: We recommend splitting any unconnected pieces into their own file to avoid issues while uploading.

We recommend splitting any unconnected pieces into their own file to avoid issues while uploading.

If you are still experiencing this error when uploading a single mesh file, please make sure your model does not contain any separated vertices, inside or outside the model, and use the previously linked tools to fix any of these issues.

Example: